HIGH MIX: Rethinking the Blueprint, Forging Ahead

Reindustrialization news for September 29, 2025

Welcome to HIGH MIX, our weekly newsletter about the reindustrialization of the United States.

“When 400,000 Manufacturing Jobs Go Unfilled, It’s Time To Rethink The Blueprint” FORBES

One statistic hits like an alarm clock for the reindustrialization dream: 400,000 U.S. manufacturing jobs sit vacant, a hole in the fabric of American industry.

Natan Linder, a manufacturing veteran, doesn’t mince words—this is a structural failure of the “blueprint” we’ve used to attract and retain talent.

His argument at its core is a plea for reinvention, saying that the old model—relying on high school career days and generic job fairs—treats manufacturing like a relic, ignoring the sector’s evolution into a high-tech arena blending AI, robotics, and sustainable processes.

It’s a timely critique.

He points to a 2024 Deloitte survey showing only 20% of Americans view manufacturing as “cool” or viable, a perception rooted in outdated images of grimy factories rather than the reality of $60,000 starting salaries for CNC machinists. Delving deeper into demographic shifts, an aging workforce (average age 44, up from 40 in 2010) and a 30% drop in vocational enrollment since 1990 exacerbate the issue.

It’s a failure to market the sector’s intellectual appeal. Why not highlight how a welder today can use AR glasses for precision work, or how supply chain analysts could wield data science to outsmart global disruptions?

Linder calls for a “new blueprint”—vocational pipelines starting in middle school, partnerships with tech firms for apprenticeships, and campaigns that frame manufacturing as the backbone of innovation, not drudgery.

Make manufacturing cool again. Firms must lead with storytelling, not just paychecks, to lure Gen Z.

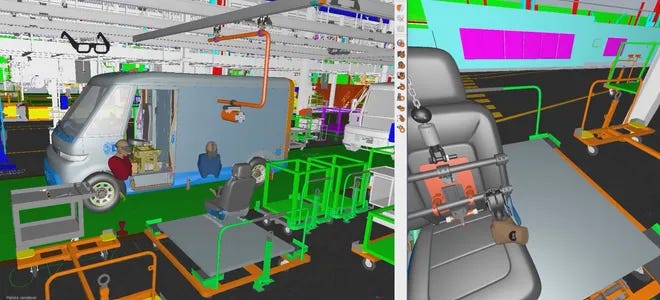

“Inside GM’s virtual assembly line where AI and VR revolutionize car manufacturing” USA TODAY

A designer in Detroit slips on a VR headset, steps into a virtual Cadillac, and tweaks the dashboard feel with haptic gloves, while a colleague in California chimes in real-time. That’s the magic of General Motors’ Virtual Reality Lab in Warren, Michigan. GM’s VR setup uses life-size digital models, allowing teams to “walk” around vehicles, adjust ergonomics, and collaborate globally.

“Volvo Cars to produce new US model amid tariff pressure” REUTERS

Volvo Cars is making a calculated move to ramp up U.S. production amid tariff pressures, announcing plans to produce a new next-generation hybrid model in the United States by the end of this decade.

This comes alongside the start of XC60 mid-size SUV production at its South Carolina plant by late 2026, a strategic adjustment to navigate the 27.5% levy on foreign vehicles until a new EU-U.S. trade deal takes effect, reducing it to 15%.

“There Are More Robots Working in China Than the Rest of the World Combined” NY TIMES

Over two million robots are already at work in Chinese plants, with nearly 300,000 new installations last year alone, dwarfing the U.S.’s modest 34,000.

This surge, part of a decade-long push under the “Made in China 2025” initiative, has catapulted the country’s share of global robot production to one-third, up from a quarter in 2023.

Nearly three-fifths of those robots are now domestically made (in China), and China’s manufacturing output now accounts for nearly a third of all manufactured goods worldwide, exceeding the combined efforts of the U.S., Germany, Japan, South Korea, and Britain. Factories there have been adding over 150,000 robots annually since 2017.

China’s state-backed strategy—policy directives, public capital, and a national robot deployment plan issued in 2021—has created a self-reinforcing loop: more robots mean more efficient factories, which in turn demand even more robots.

This isn’t organic growth.

The implications for U.S. reindustrialization are both daunting and instructive.

For America, lagging at five times fewer robots per factory than China, the gap feels like a chasm. U.S. firms can attempt to leapfrog by focusing on high-value, flexible automation, like collaborative robots (cobots) that work alongside humans, rather than China’s rigid and mass-scaled dark factory model.

“Niron Magnetics breaks ground on Sartell manufacturing facility to scale up cutting-edge technology” CBS NEWS

Imagine a world where the magnets in your EV motor or smartphone don’t rely on rare earths mined from conflict zones— that’s the promise of Niron Magnetics’ new facility in Sartell, Minnesota, where groundbreaking happened last week.

The science is straightforward but revolutionary. Niron’s process, born from University of Minnesota research backed by a 2011 DOE grant, creates magnets with performance rivaling rare-earth ones—strong enough for EVs and cell phones—without the environmental toll of mining neodymium or dysprosium.

We spoke to Niron’s CEO Jonathan Rowntree in July:

Opinion: Forging Ahead

Paul T Silhan

Dear HIGH MIX readers, let’s pause so the lessons we’ve learned can settle in.

Over the past few months, we’ve journeyed through America’s industrial makeover as co-authors in a story that’s rewriting itself. I’ve had a lot of fun covering this inexhaustible topic, and I’d like to thank Joel Johnson for the opportunity to write this newsletter.

Reindustrialization, as I see it, is a concoction of policy, people (that’s you), and good old fashioned cash turning literal rust into GDP like alchemy. It’s impressive when it works and those who can pull it off are our MVPs. Bringing you closer to the people who make this magic happen is a key part of Tool or Die’s mission.

We’ve talked about everything from the quiet efficiencies of tools that predict failures before they happen to the bold gambits of sovereign funds channeling public power into private innovation.

We know that reshoring thrives when capital flows as a directed stream, nurturing sectors like semiconductors or aerospace where U.S. talent can outshine China’s sheer scale.

We’ve also seen how the old method of trade barriers—those blunt instruments of tariffs and incentives—can jolt supply chains awake, forcing a reckoning with dependencies that once seemed unbreakable. They’ve compelled companies to rethink not just where things are made, but how they’re made.

We also learned that protectionism alone doesn’t build; it clears the path for ingenuity to take steps forward.

It’s obvious that our main competition in this effort is, and has been, China. Offshoring was a mistake. We know that now, and the current administration is a bull in a China shop. But this industrial resurgence has to persist for the next several administrations to have any lasting effect.

As always, at the center of HIGH MIX has been the human element—the beating heart we’ve revisited time and again. We’ve discussed how academies and apprenticeships can transform perceptions and set young Americans up for success—and how old-school knowledge is about as valuable as it gets.

Our studious readers already know this, but the value of experience is hard to quantify and handing down that knowledge is crucial as the younger generation steps in for retirees on their way out.

We’ve learned that the path forward demands more than subsidies or slogans; it calls for a cultural shift, where factories become incubators of ideas and regulations don’t hold them back.

Manufacturing’s future is humans and machines working in tandem, where a welder with machine vision spots defects, or a line supervisor uses AI to optimize flows, all without losing the deft human touch that makes something “well made”. And reindustrialization succeeds not by mimicking yesterday’s giants, but by learning from their cautionary tales and embracing tomorrow’s hybrids—flexible, people-powered, and unapologetically American.

Readers: you’re smart, driven, and in some cases, even pulchritudinous. You’ve absorbed what you could along the way. Kudos. It’s a bit cliché to say we have the best readers but it’s true. The reindustrialization movement is overflowing with talent.

Here’s to the makers, the menders, and the dreamers who’ve walked this road with us. The next step is rolling up your sleeves, whether in a boardroom or a workshop, and building America’s future.

The forge is hot, the tools are sharp—now, go build something meaningful.